Greenbrook Design Center

***Latest Post Update 8/21/2018

CHECK OUT OUR NEW SHOWROOM!

***Latest Post Update 10/30/2017

WE ARE MOVED-IN AT THE DESIGN CENTER!

WE ARE EXCITED TO SHARE WITH YOU OUR

DECISIONS, DETAILS, & DESIGN IDEAS!

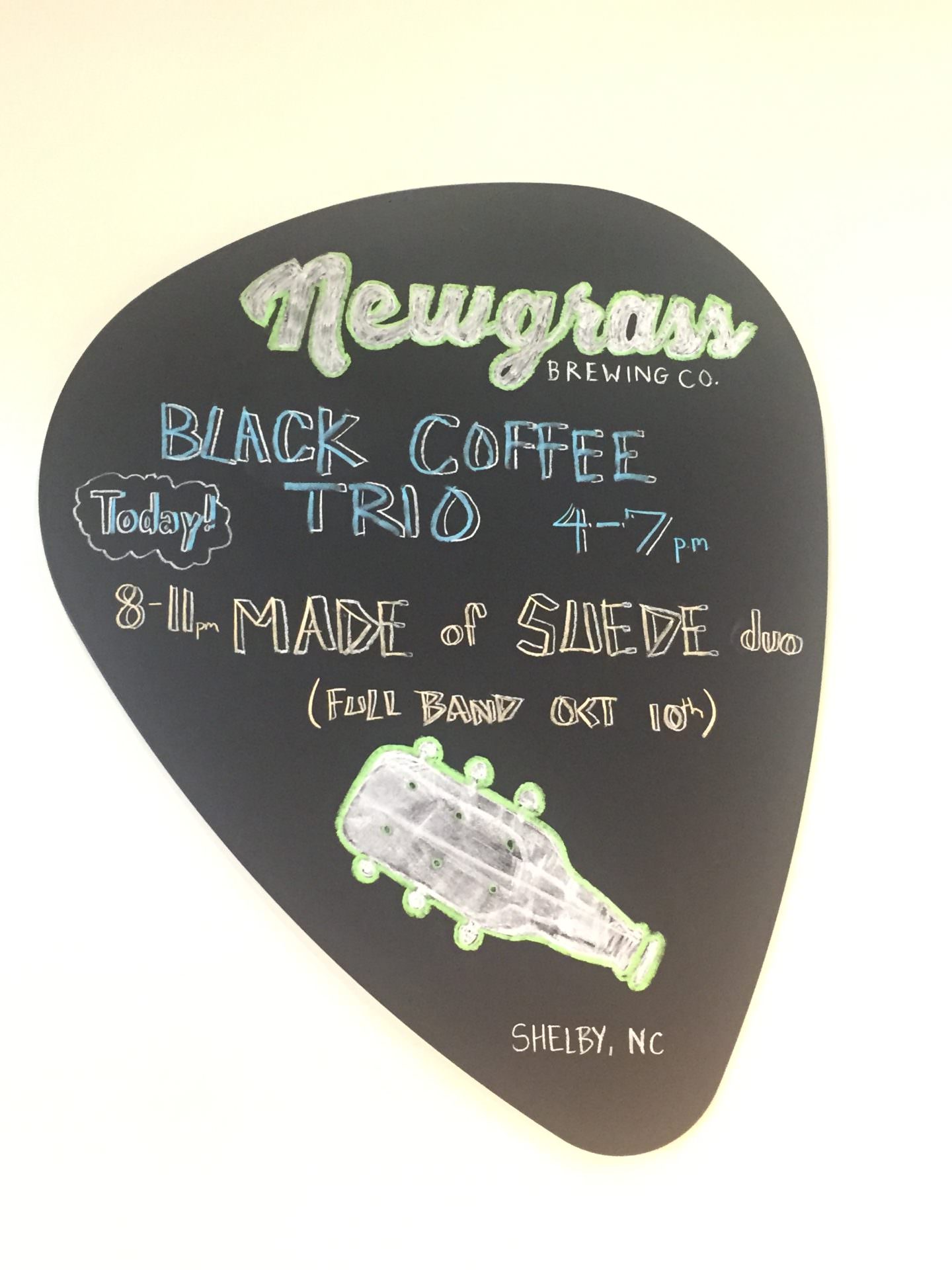

OPENING FALL 2017 TO UPTOWN SHELBY!

GREENBROOK DESIGN, KITCHEN & BATH HOME DESIGN CENTER

Inside the Design Center, you will find a unique one-of-a-kind showroom. The kitchen and bath home design center will be sure to appeal to homeowners, interior designers as well as contractors. Plan to be intrigued and watch us GROW in Uptown Shelby.

We are excited to be under construction! Stay up-to-date with what’s happening as we share more details on this page!

OUR JOURNEY TO UPTOWN SHELBY

Location Address: 112-1 North Lafayette St. Shelby NC 28150

Construction has officially started! This is formally known as part of the Campbell building.

Here is a sidewalk view (before) of the Design Center. We have great plans in the works.

Storefront prior to construction.

Update 10/30/2017

AND WE MOVED IN!

It’s been a busy few weeks. Before during and after moving is a big job. For this update, I am adding just photo’s be sure to read the captions for details.

Featured lighting & James Martin Vanities!

Stickwood installed!

Walker Woodworking door display.

Wellborn display in progress, of course, we still need a backsplash, appliances & lighting!

This backsplash is going somewhere…

Hardware towers and more.

Our Walker Woodworking Display! In progress, appliance install underway!

Subzero appliances on standby for install. This will be for our Walker Woodworking kitchen where we will be hosting live cooking demonstrations.

Dura Supreme display in progress, of course, we still need a backsplash, appliances & lighting!

It was exciting to reveal our tile floors that had been covered up for many weeks.

Mahogany doors being built in our shop and what they look like the day of installation. There were four doors total to make and the sizes 3′ wide by 8.5′ tall. Travis did the majority of the work on these with help from Chris Masters and Justin Webb (not pictured).

Update 9/16/2017

ANOTHER GREAT WEEK OF PROGRESS!

If you look back through this post – you notice that I keep the most recent updates at the top. A year ago on 9/17/2016, I made a post about how the work had stalled. Things are finally happening at the Design Center and we can’t wait to be able to move into our new space.

SATURDAY WORK & SATURDAY SURPRISES.

We have been working lots of Saturdays here at Walker Woodworking. Not only do we have a packed production schedule, but we also have design center items to make. One of my early visions for this building was the exterior. We were unable to make some of the changes I wanted because of the historic preservation rules. But I felt that the doors just looked so common and small compared to the massive size of the windows. My idea was to bring in taller wood-framed doors and I volunteered Travis to make them (he wasn’t thrilled about that idea at all). I talked to him into getting it done, knowing that in the end, it would be something he would be proud of that he personally had a hand in making. Travis delivered the doors yesterday (Friday) and today we went by so that our daughters could see the progress. We were pleasantly surprised to see the doors getting installed and another step toward getting this project completed.

DISPLAY CABINETS GET INSTALLED.

We have had a huge warehouse full of cabinets, lights, sinks, hardware displays and all sorts of things that we have collected over the last two years for this project. So when we started loading up the truck to take to the showroom to be installed – it was a really exciting moment for me. I won’t lie – I have been impatient and I am ready to get moved in. The gray cabinets are for our Wellborn display and the white cabinets are Dura Supreme. These are the 2 semi-custom cabinet lines we will be offering.

Cabinet Install – Phase 1

Update 09/05/2017

FLOORS – A BIG DECISION!

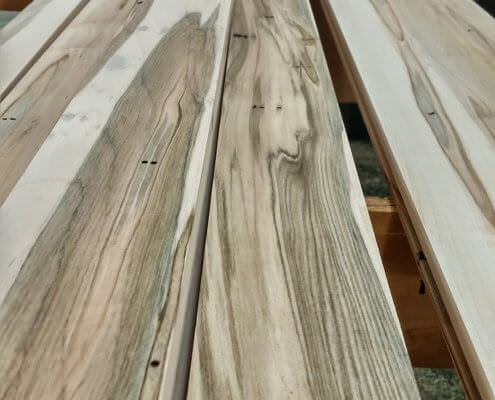

One of the things I have learned during this whole process is that I can’t always let my personal preferences lead my decisions. I really wanted a stain on these floors because I really love to see color in wood finishes. I would have been happy with just about any stain color but the light gray was my favorite. I ultimately decided to go natural for two reasons, I felt that over time the lighter finish would be the most neutral and organic color to work our displays and decor around. The other reason I went with natural is that I felt it stayed true to the original elements of the building. I am so glad I went with the natural finish, these floors are truly beautiful and full of history. I would love to hear your thoughts – comment below!

Floors before and during finishing. The final decision of the stain choice was to go with Natural!

FLOORS AFTER.

You may notice in the showroom, there are actually three different types of wood used. Maple, Pine, & Oak. Over the years and due to multiple renovations, the flooring is what adds so much character to our space.

Update 8/20/2017

CEILINGS GET A MAKEOVER IN WHITE.

I had a few people tell me that I should keep the ceilings black but I just couldn’t do it. I am actually a big fan of black ceilings I have black ceilings in my basement, most showrooms have black ceilings but for me, changing the ceiling back to white was the easiest decision I have made so far. Without a doubt, these ceilings make this building. They are original to the building and something we needed to show off. It has been amazing at how much bigger and brighter the space is.

Here is a before and after of the ceilings before the lights were installed. The before and after photos were all with natural light from outside.

Update 07/17/2017

WE ARE FINALLY SEEING PROGRESS TO GET EXCITED ABOUT!

This has for sure been a test of patience for us over the last 2 years but I am happy to announce that things have been moving along again. Of course, if you have been following our social media sites you already noticed! Although things have been slow to move along, this week we will begin to see lots of progress. Some of the major things to be done include installing windows and doors which mean there is some interior and exterior work to finish up.

In order to keep the historical preservation of the building, several of these interior and exterior items had to be special ordered. Although we don’t own the building, keeping true to these historical elements is important to us as well. Once the doors and windows are installed, we hope to start seeing some paint on the walls and ceilings and trim work getting done. From there, things should move relatively quick. This also means that Walker Woodworking will be busy building some specialty items as well.

For the latest information, we suggest that you follow us on social media. With the new ‘stories’ on Instagram, we are able to introduce more behind the scene pictures with captions, which tell you more about the locations and pictures as you view them. We usually visit daily and post updates.

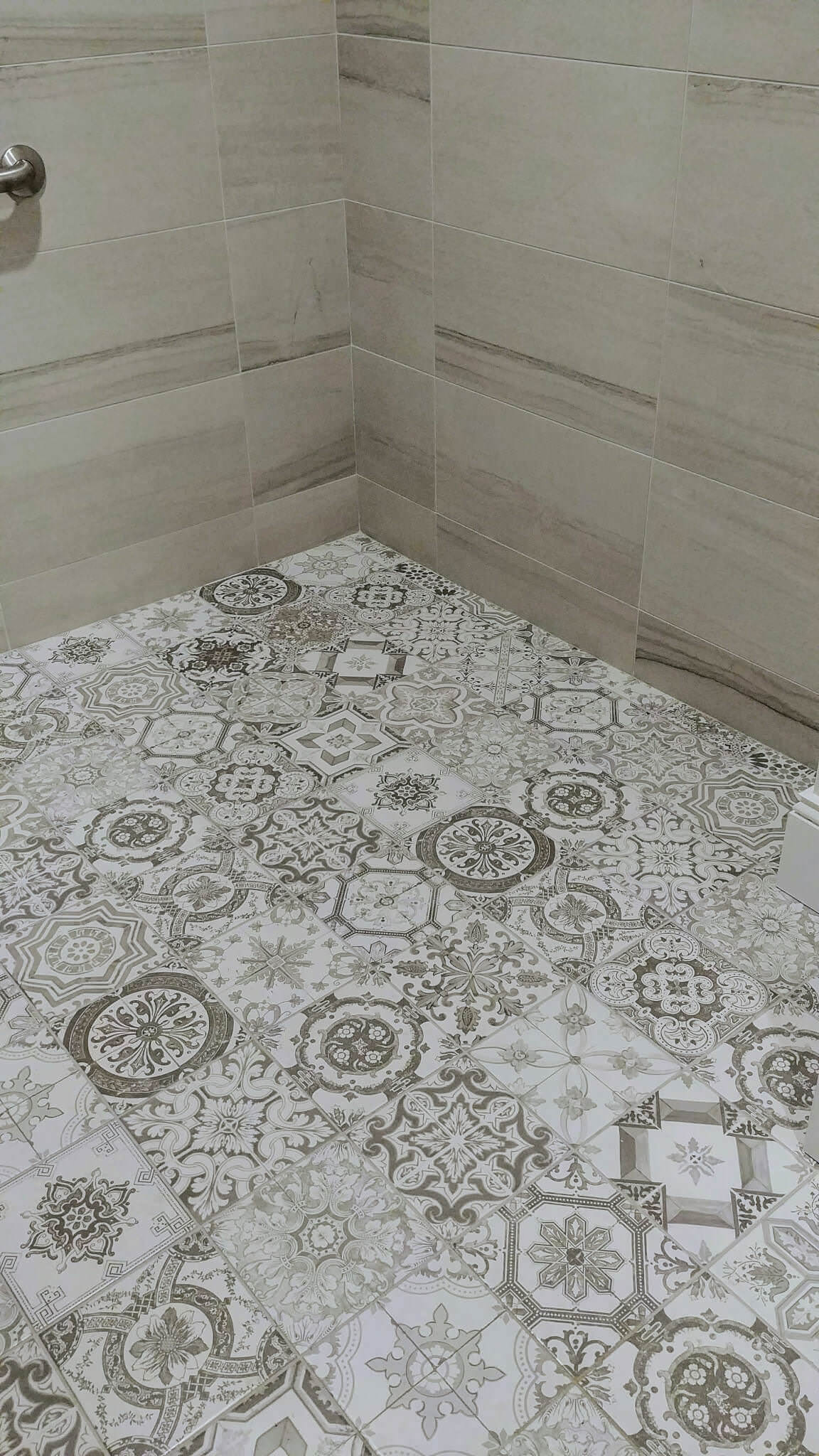

Interior tile work was completed last week.

Update 9/17/2016

AND THE WORK HAS STALLED…

Construction of our Design Center has been stopped temporarily due to a Federal Grant approval process. Stay tuned, construction is scheduled to resume November 3rd.

Meanwhile, our team is still making plans, making selections and getting excited about moving to Uptown Shelby.

MAKING SELECTIONS

The process of making selections as been underway for a while now but there is still lots to do. We thought it would be interesting to see how we take certain design elements and put them together for the final product. Often times HGTV makes the construction and remodel process look fast and easy in a 30 minute TV show, but the reality is a much longer and very complex process. A lot of time and thought from multiple sources of professionals goes into making a project of this proportion come to life.

TILE

This past week we went tile shopping; Wendi and I (Stacey) spent a day visiting several tile centers – 5 in all. We have several areas that we will need to select tile. The construction plans will be adding bathrooms and office space. Although we made some progress we still have a lot more to do and more to select. Here is a peek at some of the fun things we found. Did you know Charlotte has so many great tile centers? Daltile, Emser, Florida Tile, The Tile Collection, & Crossville Tile.

Update 5/21/2016

AND THE WORK BEGINS…

Construction officially started in early March, and the bulk of that time has been spent in the basement. More updates coming soon.

View from the mezzanine to the main showroom floor.

Original Post 5/13/2016

HOW WE GOT HERE…

When Travis and I purchased a CNC Router at the end of 2013, we never imagined how much things would change for us and our business with Walker Woodworking. We certainly had much to learn and we definitely had many challenges to overcome, but we will save that story for another day. The CNC router enabled us to take our company to a new level with innovation and technology and while we have embraced these changes, we also had new needs that our current space could not provide.

Learning the CNC software and getting the process up and going was initiated by Brandon Fitzmorris. Brandon was our lead engineer and helped through the initial transition. As many people may remember, our designer at the time in 2013 & 2014 was Jeneane Beaver. Jeneane had just had her first child and with another on the way she decided that she wanted to stay home and be with her kids; a decision that we respected but it left us in a position to find a suitable replacement. Brandon was eager to accept the challenge and therefore we had yet another position to fill. By the end of 2014, we had Brandon in his position as Designer and a new engineer in place, with the need for an additional engineer.

Travis and I had been debating ideas to build a new shop or open a new showroom. While we were not necessarily making any immediate plans for one or the other, we were approached in the early summer of May 2015 by excited new owners of a building in Uptown Shelby. They had heard that we may be looking for space and we were very eager to see the space. Soon after we were signing a lease. Since that time we have been patiently waiting for the process of architects, engineers, and permits from the City of Shelby to run its course. Planning the space with the owners took some time, but we are thrilled with the end results.

Meanwhile, we have been making necessary staff changes in anticipation of this new showroom. Adding staff in space you don’t have has certainly put a strain on our working environment but we became creative and made temporary adjustments to make it work. Over the last year we have added to our staff: Jan Blanton – Design Assistant, Tyler Triplett – Engineer, and most recently Ryanne Turner – Design Assistant. Marie Walker, a longtime administrative assistant, is patiently awaiting the new showroom to have her own office. During this transition, she has moved to a home-based office with me (Stacey Walker) and continues with day-to-day duties. We are all looking forward to the new Design Center.

A LITTLE HISTORY…

Campbell Building – full corner view

The Design center building itself is located right on the corner beside of First Baptist Church. Originally, construction started on the building in 1928 and was completed in 1929. The first use was a general store, then it became a pharmacy and had a little restaurant in the mezzanine area. It was later a furniture store and they sold toys in the basement area. Within the past 10 years, the last to use the building was a furniture store. As far as we know the 2 upper floors have never been used for much except storage.

Over the years the building was handed down to generations of the same family. The new owners are the first ones to actually purchase the building. Kay, the previous owner, is the great-granddaughter of the men who built the building. One was a steelmaker and another owned a brick factory and these two men had children that married each other. That couple had a child, and that child was the parent of Kay and Edgar.

At one point in time, all the stairs and railings were painted bright orange! A few years back, Edgar took all that paint off himself and refinished each of the railings and banisters on site. (*Please feel free to comment in the feed if you have any other information about the historic building, we want to give as much accurate information as possible about the building)

The interior of this building has some great features that are original to the building that we want to preserve and maintain as much as we possibly can. From the original tin ceilings, the beautiful wooden staircases, and the pine floors. We worked diligently with the owners & architects to help make this happen, but in order to bring the building up to date with today’s codes, there will be a big transition in some areas inside and out that can’t be avoided. In the near future, the upper floors will be renovated as well. The 2nd floor will be Uptown Indigo – an event space and the 3rd floor will be the residence of the building owners.

Old Newspaper – Campbell Building

Old Ads From Furniture Store

Old Newspaper Ad

Follow us on Facebook & Instagram – #walkerwoodworking #greenbrookdesign #uptownshelby #shelbync for more photos and event updates!