Custom, Semi-Custom, Stock Cabinets

What is the difference between Custom, Semi-custom and Stock cabinets?

If you’ve already renovated a kitchen or are just beginning the process, you know how overwhelming the details can be. One of the many things to consider is whether or not you want to purchase custom or semi-custom cabinets and what the differences are. This blog will primarily focus on the differences between stock, semi-custom, and custom kitchen cabinets.

The first thing to know when noting differences between stock, semi-custom, and custom cabinets is that the terms refer to the type of production methods used to make the cabinets, and not to the quality of the cabinets. If you want more information about the quality of materials and construction methods, then you can find that in this blog. (stacey will link)

Stock Cabinets

Stock Cabinets by Wellborn

Stock cabinets are readymade, pre-manufactured cabinets, meaning they’re mass-produced in a factory and ready to ship when ordered. They’re sold in modular units, and no customization is available. What you see is what you get! The advantages of stock cabinets are affordability and a quick delivery time. However, you usually have a limited selection of styles, shapes, colors, wood types, etc. Delivery time is typically 1 to 3 weeks from the time of your order.

We recommend using stock cabinets if:

- You are looking for a low cost solution to your cabinetry needs.

- You can save money by installing them yourself.

- Stock cabinetry is the quickest solution if time is a factor.

The disadvantages of Stock Cabinetry:

- Finish & color selections are limited.

- There are standard height dimensions for base, wall, vanity and tall cabinets. Stock cabinets cannot be modified.

- Generally stock cabinets will last 5 – 10 years.

Standard Width: Start at 9″ with 3″ increments to 48″

Standard Depth: 12″ for wall cabinets, 24″ for oven, base, and utility cabinets.

More information about Wellborn Cabinets

Semi-Custom Cabinets

Semi-Custom Cabinets by Dura Supreme

Semi-custom cabinets are basically stock cabinets with extra detailing options. The basic cabinet sizes still apply, but consumers have the option to change certain dimensions, like resizing the cabinet drawers and door fronts, or increasing/decreasing the cabinet depth. The advantages of semi-custom cabinets is that you get the feeling you have some individual input into the design (however limited) without the cost of full-on custom cabinets. Sometimes that’s all you need to get great cabinets without the expense of a custom job. Semi-custom truly is the best of both worlds. Delivery time is typically 3 to 8 weeks from the time of your order.

We recommend using Semi-Custom cabinets if:

- Semi-custom cabinets offer a great balance between stock & custom cabinetry. A budget friendly choice for a simple upgrade to your home.

- Incorporate stock options with modifications and customization to feel as if you are involved in the design phase.

- Quick lead times can make the process move along faster.

The disadvantages of Semi- Cabinets:

- Hardware: better quality hinges and slides are available as an upgrade only.

- Construction: Although made to the client’s size requirements, semi-custom cabinets are predetermined sizes and often fillers are used to fill areas which can limit your storage options.

- Semi cabinetry typically will last in the home / office 10 – 20 years.

Standard Width: Start at 9″ with 1″ increments to 48″

Standard Depth: Can be reduced or increased according to the manufacturer’s guidelines.

More information about Dura Supreme Cabinets

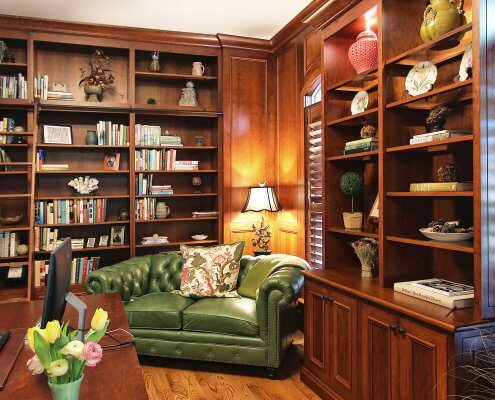

Custom Cabinets

Custom Cabinets by Walker Woodworking

Custom cabinets are built to your specifications, so they can be pretty much anything you want! When designing custom cabinets, we start with your floorplan and window and door locations. We then determine what your appliance preferences are and then we custom design your cabinets around that incorporating all your accessory and storage ideas. Because of this, custom cabinets are expensive, labor-intensive, and usually take a few weeks or months to complete. Custom cabinets are built by skilled carpenters, and manufactured on a build-to-order basis.

We recommend using Custom cabinets if:

- You are building a new home or if your floor plan is more complex and requires customization by not using standard sizes. Custom cabinets are built to fit.

- Custom cabinets allow the consumer complete freedom in the design, style and construction of the cabinetry. You don’t have to settle for average, you can add all the bells and whistles!

- Custom cabinetry is built to last a lifetime.

The disadvantages of Custom Cabinets:

- Timing: generally custom cabinets take the longest. The design and construction phase are more detailed. All work is done by skilled craftsman, therefore the production takes longer.

- Huge cost difference: No doubt custom is the most expensive of the three, but the value received will be well worth it!

- I wish I could come with another negative but I can’t. If you plan on living in your home for a long time and quality is very important, then custom is for you!

Standard Width: Customizable

Standard Depth: Customizable

The Biggest Difference is PRICE

As you may have guessed, the more options you have with customization, the higher the overall price will be. Another advantage to having more custom options is that you are usually able to get a lot more storage gadgets such as spice pullouts and drawer organizers. Rev-A-Shelf has an endless supply of items that can be added into custom cabinets and semi-custom cabinets. The ability to build custom hoods can also add a unique complement to your overall design. Some Kitchen and bath dealers (like us) have the ability to provide semi-custom cabinets while being able to offer custom built pieces such as a hood or hutch as enhancements to your order of kitchen cabinets.

The possibilities are endless, you just need a creative designer to make it happen. Afterall, your kitchen is the heart of the home, where you and your family spend lots of time, and you’ll want it to be functional, durable, and beautiful!

Call us today and see how we can design a great kitchen at the price-point that is right for you.

What kind of cabinets do you have in your kitchen? Share your experiences and recommendations! Was this information helpful? Share your comments.